ENGINEERING

Each set of Zhongxin Forged wheels are meticulously designed, engineered, and crafted in our factory. with over 20 years of combined forged wheel experience allows us to have full control over the quality of our process. Each order goes through Finite Element Analysis (FEA) testing to ensure the most optimal combination of lightweight, durability, and strength.

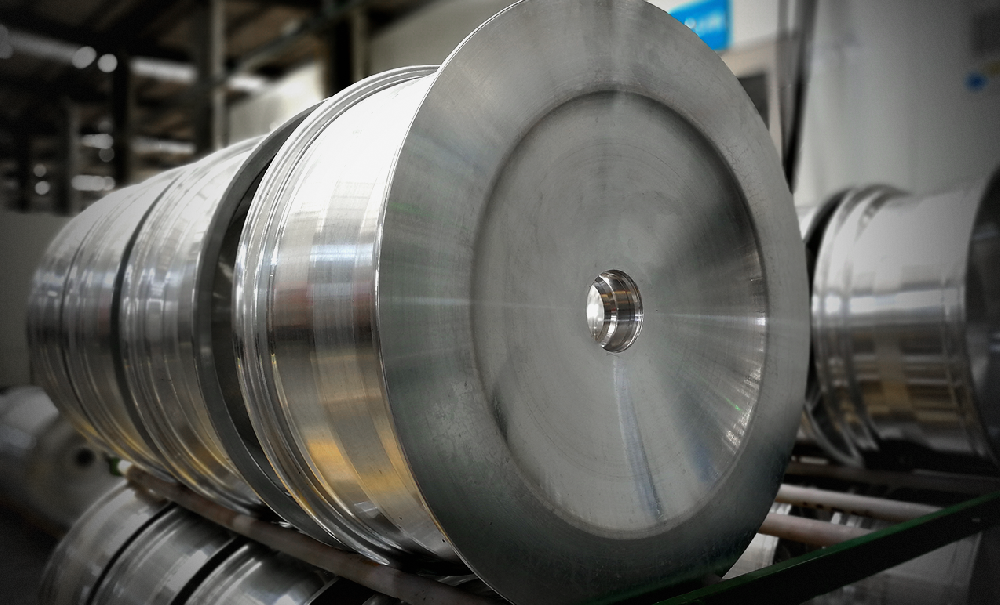

MATERIAL

Aero-space grade 6061 T6 forged aluminum, a material that combines relatively high strength, good work ability and high resistance to corrosion. A raw forging formed when aluminum bar stamped by over ten thousand hydraulic press machine.

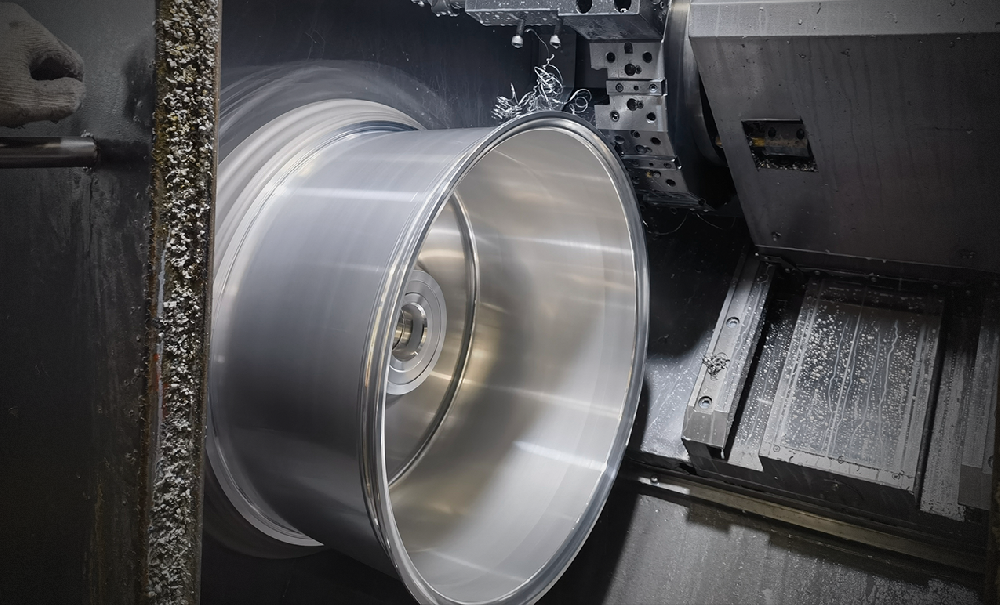

LATHE TURNING

The key step in manufacturing a forged wheel is lathe turning. The raw forging is lathe-turned from the front and rear, creating a profile that maximizes concavity. In this step over 70% of the original material is removed, utilizing the most weight reduction.

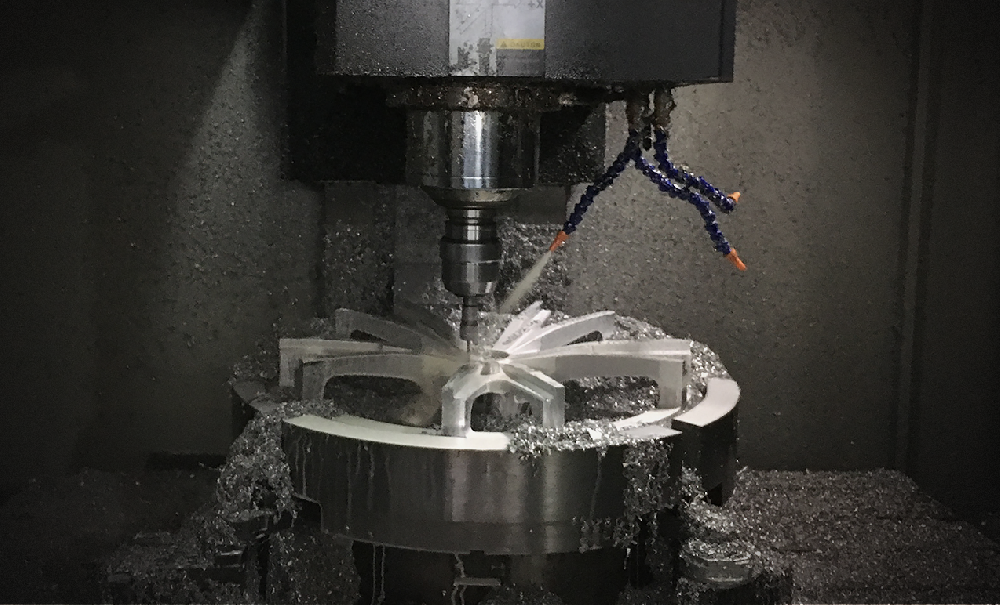

DESIGN MILLING

Once the profile is completed, the forgings are then turned over to the mill process. The mill process is where the design comes to life. As mill cycles run through a series of pre-selected tool sets and milling paths that can take up to 4 hours per wheel to achieve the utmost precision.

FINISHING

ZHONGXIN’s significance and understanding of excellence in finishing surpasses the industry by advanced Techniks and quality assurance perfection. Passing the hands of qualified specialist, the process of preparation, coating and assembly are imperative in bringing esthetic art-form to life.